Substation automation systems are used by companies where power availability is critical, and energy control and monitoring is a necessity. The demand for substation automation solutions has evolved. Aimen Abd-El-Azim, Global Partner Program Leader, Substation Automation EcoXpert, on substation automation and the changes in the market.

The data-hungry digital economy requires highly efficient power networks. The demand for high-quality and reliable energy systems grows across industries as digitization continues to change our world.

The modernization of smart power grids, integration of renewable energy sources and criticality of energy availability, drive the increasing demand to monitor power-related information from the edge. Smart monitoring enables businesses to control and protect their facilities and energy assets.

Substation automation systems are used by companies where energy availability is critical, and energy control and monitoring is a necessity. By gathering data from all the equipment and the field they can avoid blackouts and intervene to protect the power network and their facilities.

For companies such as system integrators and medium voltage panel builders, additional opportunities arise with power-critical facility owners asking for this level of monitoring and the pro-active maintenance and management it enables. To respond to this demand, Schneider Electric launched a new certification in its EcoXpert partner program: Substation Automation.

Certified substation automation channel partners have proven expertise in the deployment of high-and-medium-voltage substation automation systems, using IEDs (intelligent electronic devices) and software tools. These enable utilities and electro intensive end-users to improve observability, controllability, and reliability of their electrical grid.

In this interview, Aimen Abd-el-azim, who is responsible for the program, talks about the new partner program, key evolutions in substation automation, and the market shifts which drove the demand and opportunity for a Substation Automation partner certification.

Substation automation solutions – collecting information from the field to act upon it

Aimen, you’re in charge of the substation automation certification since early this year. What did you do before?

Aimen Abd-el-azim: My background is in energy automation. It includes the substation automation offers, which has been a significant part of my activities during the eight years I work at the company.

I started as a tender engineer in France, responsible for RfQs related to substation automation systems. Then, I moved to the Gulf, with the same role focusing in the MENA region, then as solution architect and tender manager within the oil & gas segment where substation automation is essential.

Then, I worked in marketing as an offer category manager before taking up this new role.

Can you tell us more about this substation automation offering and why companies deploy substation automation systems?

Aimen Abd-el-azim: Our substation automation offering was built with existing energy automation components and consists of software and hardware that helps end-users to monitor, control and protect their electrical assets to reduce incidents and the duration of a power outage.

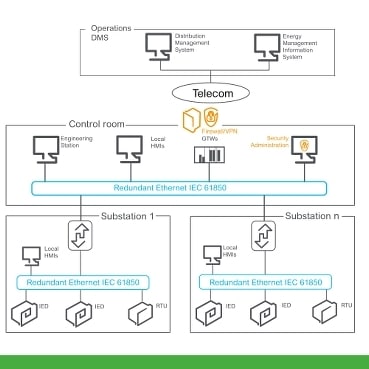

We provide substation automation systems – or energy control and monitoring systems – for simple centralized substation protection and control panels and for more complex, distributed systems whereby the solutions differ and depend on the architecture.

The increasing demand for the advanced power control and monitoring possibilities which are offered by substation automation, among others, comes from power-critical facilities such as airports, data centers, and healthcare facilities such as hospitals. Additional drivers for the advanced power control and monitoring possibilities that substation automation offers is further fueled by the growing importance of renewable energy and cybersecurity.

Customers install substation automation solutions to make sure they have the highest possible energy availability. The hardware and software from our substation automation offering enable companies to simplify the collection of data from the field whereby the user can act upon the gathered intelligence.

Substation automation is the tool for customers to make sure their entire electrical network is working within the right environment and optimal conditions at their facilities.

In critical infrastructures, this can be achieved in duplicating the main hardware with different algorithms to ensure one will operate if the second fails or is temporarily out of service, implementing fast self-healing grid for electrical network reconfiguration and protecting the facility from threats with cybersecurity which is getting more and more in top of the mind of decision makers.

In other words, the substation automation offering is all about analyzing and acting fast to ensure the safety of the people, secure the power and the assets to have everything running smoothly.

Power-critical facilities increasingly require the monitoring, control and protection capabilities of substation automation systems

What types of end-users and facilities use substation automation solutions? There are the electrical utilities in transmission and distribution, and you mentioned oil & gas companies.

Aimen Abd-el-azim: Historically, end-users were from large and critical infrastructures such as electrical utilities in the transmission or distribution part of power grids and indeed the oil & gas segment.

Today, energy is a major stake in most of the sectors. Electro-intensive companies are definitely part of it. These are companies whose electricity consumption represents a critical load and are often substantial industrial players with direct connections to the grid. Also concerned are power-critical facilities such as healthcare facilities, data centers, process industry buildings, and airports, to mention a few.

The facilities can range from substations in electrical utilities to large data centers and, increasingly, smaller facilities.

With power-critical facilities we’re in an area where there is already another certification which we tackled before: the Critical Power EcoXpert certification. What’s the difference in focus between both certifications in this market?

Aimen Abd-el-azim: Critical Power EcoXperts deploy solutions and projects to enhance the power quality and reliability of their customers; we recognize them for their competencies to optimize network management and improve energy efficiency.

To do so, they integrate connected products that monitor the energy from both a quantity and quality perspective, and that correct the disturbances passively and actively. So, they use power meters, quality meters, HMIs, Special Power SCADA Operation and more.

Substation automation EcoXperts, on the other hand, are specialized in delivering energy management projects to control, monitor, and protect the medium voltage and high voltage network, as mentioned. So, they ensure high availability, cost reductions, optimization of the equipment that is used, and extend the life of that equipment.

You could say that critical power is more about the efficiency of the network, while substation automation offers a capability for customers to act and protect their facility. One EcoXpert having competencies in the two badges can be recognized with both critical power and substation automation certifications.

More power generation companies move towards renewable energy with, among others, solar and wind projects. In these projects substation automation plays a key role within the distribution network as well as the renewable plant and interconnection with the grid.

And what types of channel partners are there in substation automation and thus this new certification?

Aimen Abd-el-azim: In the substation automation EcoXpert certification, there are three types of partners.

- The first group consists of specialists in engineering solutions who focus on bringing together substation automation hardware and software, in a centralized or distributed system.

- Second, there are medium voltage panel builders using connected products. These are partners that want to differentiate themselves from their competitors by bringing together the connected products and edge control in their basket; we help them move from panel building activities to energy management solution expertise in building medium voltage energy and substation automation.

- Third, some contractors have the system engineering capability to develop substation automation solutions as part of a turn-key project.

The increasing importance of expert partners in substation automation

How did the opportunity to work with partners grow among the various end customers, were they willing to do so since the start?

Aimen Abd-el-azim: The role and acceptance of partners are viewed differently in the business of substation automation, depending on the geographies and the segments.

Almost ten years ago, we started to have a few successes for centralized substation protection and control panels in regions with interesting potential such as the Middle East and Africa.

The willingness to work with partners grew over time while the substation automation market also grew in general. When electrical utilities was ready to accept our partners, we started to address this segment as a pilot, with success and a promising outlook across all three types of partners I mentioned.

Now, the demand for substation automation growing in the power-critical facilities in which we have the Critical Power EcoXperts, we have substation automation certification to enable partners to extend their portfolio and grow their business with all the mentioned benefits.

Is the demand for substations also growing because of renewable energy projects?

Aimen Abd-el-azim: We are in a new world of energy, in which Digitization, Decentralization and Decarbonization, are driving ways we generate, transport and distribute electricity. As part of it renewable energy is a growing area.

Indeed, due to the increasing demand for electricity and changing electricity requirements landscape, more power generation companies move towards renewable energy with, among others, solar and wind projects.

In these projects, substation automation plays a key role within the distribution network as well as the renewable plant and interconnection with the grid.

The market of substation automation continues to grow with new substations. Yet, there are also quite some substations with older material and systems that need to be retrofitted to meet the demands of a changing grid and energy landscape?

Aimen Abd-el-azim: I would rather say there is a general growing demand in brownfield. First, projects can be about the refurbishing the obsolete systems and components, and migrating to new technologies to meet the latest state of the art architectures and application features, for instance, to align with regulations, improve efficiency, reduce costs and so forth.

It’s also about the digitizing of a facility thanks to communicable devices to allow better control and monitoring.

Connecting the field and edge layer: intelligent maintenance and management with EcoStruxure

Connected devices such as IEDS (intelligent electronic devices) or remote terminal units, which are vital in substation automation, exist for quite some time in substations. What has been changing in the solution field with, for instance, IoT (the Internet of Things) and the solutions you offer?

Aimen Abd-el-azim: Connecting IEDs from the field to the edge control and monitoring layers enables far more pro-active operations, helping the users to take right decision to avoid a failure or perform a corrective action and; for instance, recommend a maintenance activity or any other form of anticipation that seek to, at least, improve the quality and efficiency of the equipment.

Gathering data in real time from the field IEDs to the edge layer is this main change for substation automation. This is digital transformation. It allows us to trigger the full strength of the data, which in our case provide us a clear overview of the electrical network and the environment in which the electrical assets are evolving. This was not the case in the past.

And with the edge control layer and gaining an overview of what’s happening with all assets and the system overall, we’re talking about the IoT-enabled EcoStruxure platform of Schneider Electric and edge computing?

Aimen Abd-el-azim: Precisely, digital transformation I just explained is what EcoStruxure enables.

With the substation automation certification, we have solutions part of both EcoStruxure Grid to increase the grid’s reliability and EcoStruxure Power to maximize operation efficiency, the latter again bringing us to the critical power EcoXperts.

EcoStruxure is our digital, open architecture that makes easy integration of the protection, monitoring, and control of the network, enabling partners to take care of more than energy quality and reliability, as explained earlier, thanks to the EcoXpert substation automation certification.

Substation automation solutions in data centers

You earlier mentioned substations to provide power to data centers. Schneider Electric is a big player in the fast-growing area of so-called micro data centers which are designed for the edge or edge computing. Are there connections between substation automation and these types of data centers too?

Aimen Abd-el-azim: Definitely, substation automation has its play wherever energy sustainability is required, from large industries to small and critical facilities. Regarding micro data centers, we started to have some successes with substation automation, delivered by our system integrators.

I have in mind a case for micro data center of the headquarters of a bank, asking to upgrade an existing monitoring system, with automatic transfer switching controllers to ensure the continuity of power supply whether from the utility grid or its own generation capabilities.

This solution was delivered by our partner, using our smart remote terminal units. It’s an example of how data centers are upgraded as facilities increasingly generate their power. And it’s the type of project where substation automation EcoXperts can play an important role in increasing energy control and automation of such smaller facilities.

Regarding the edge and our edge solutions, there are several large projects for data centers where the edge-connected solutions from the Schneider Electric energy automation divisions have been deployed. These are also the types of projects our substation automation EcoXpert partners can replicate whenever the end customer accepts to work with partners, which, as explained before, is an evolution we’ve seen in the market overall with a movement towards partners.

On top of preventing issues from happening, substation automation systems enable to ensure the security of a facility and safety of the people working there.

Collecting all the information from all electrical assets in a facility that requires monitoring

EcoXpert is the sales channel of EcoStruxure and, as you mentioned, here, in particular, we have EcoStruxure Grid and EcoStruxure Power. What else do you offer in terms of hardware and possibly other solutions? Metering? Others?

Aimen Abd-el-azim: EcoStruxure provides data to aid the decision that helps protect people, secure assets, and ensure business continuity.

This is achieved by collecting real-time information from the field to the edge layer to control & operate. At the field we deliver connected hardware such as arc sensors, thermal sensors, tap changers, smart terminal blocks, gateways, bay controllers as well as power, quality, and tariff meters.

In addition, improved control and system performance are brought with the use of generic to advanced controllers such as automatic voltage regulator, generator management system and intelligent fast load shedding controllers, as well as other devices that we recommend to our EcoXperts.

Are the tariff meters which you mention comparable to the special meters used in buildings that enable separate invoicing, as Kevin Morin explained in an interview regarding critical power?

Aimen Abd-el-azim: Yes, exactly. Our tariff meters help to track of energy expenses and enable cost reduction. These needs are common in buildings, utilities and industries, and can be covered by our tariff meters through both critical power and substation automation EcoXperts.

Recently we published an interview on harmonics mitigation when using variable frequency drives in the context of power quality and power control, where the convergence of industrial automation and energy automation is a driver to address these challenges. What about harmonics in substation automation?

Aimen Abd-el-azim: Customers monitor their electrical network quality in measuring several variables; harmonics is a key one of them. The picture of the harmonics adds to a better understanding as it reflects a decrease in the efficiency of the electrical assets such as variable frequency drives, power motors and generators. It also shows an external pollution perturbating the electrical network and facility.

You have mentioned variable frequency drives. Usually, these aren’t in the scope of the provider of substation automation solutions as far as I’m concerned.

However, we will use PM power meters, and ION quality meters to measure these harmonics. Protection relays might also measure these harmonics in case of power transformers to identify any resonance frequency. Once available at the edge layer as part of the EcoStruxure Power and Grid, our substation automation solutions will act to get rid of this pollution.

More and more, we will move to new intelligent technologies at the level of the electrical assets and equipment with information going through fiber optics, etc. to the power control monitoring system or the substation automation edge.

The digital substation and IEC 61850 standard

You mention fiber optics. In substations overall, there is also a movement from copper to fiber optics in so-called digital substations. What is this digital substation evolution about?

Aimen Abd-el-azim: Digital substation is about combining new technologies and processes to make the electrical network smarter, more safe, compact, cyber secure and use substation data to actively improve the design, installation, operation, and maintenance for distribution and transmission facilities. Digital substation is the trend for the coming years, and the evolution it brings is happening at every level from Connected Products, including sensors, to Edge Control, and Apps, Analytics and Services, to provide end-to-end solutions.

One of the evolutions that you mentioned is the fiber optics replacing copper cables. This is an interesting one as it helped with communication efficiency and speed between the electrical assets, connected devices and edge control with new ways for data collection. I can also name the Low Power Current Transformers (LPCTs), which are current sensors providing metering and protection measurements with direct low voltage output. This new approach creates a work environment that is safe for the maintenance engineers and reduces threats for the electrical components. Then digital substation answers to the latest primary user’s concerns such as cyber secured substation automation solutions to protect the system against mal-operation or intrusion and electrical assets’ life cycle with an asset management system to help in programming predictive maintenance.

When we speak about digital substations, there is the IEC 61850 edition 2 standard since 2011. What can you tell us about it?

Aimen Abd-el-azim: IEC 61850 is an international standard that has been developed first for the utility end-user, then adopted by the major players in oil and gas, data center, and other critical industrials.

The goal was to enable interoperable communication between all components of substation automation within an electrical facility.

Edition 2 of the IEC 61850 standard is a new layer to enhance consistency between the various players. To make it simple, it fills the gaps from communication perspective to electrical assets modeling, offering multiple possibilities, such as high availability of the substation automation solution, scalability of the installation, design standardization, engineering optimization and overall cost reduction.

The Substation Automation certification across the globe and in practice

Are some countries or regions more active in substation automation, in general, and from the perspective of Schneider Electric?

Aimen Abd-el-azim: We started the substation automation for system integrators three years ago with the new certification running in a pilot mode. Since we began in the Middle East, Africa, then extended in East Asia, that’s where substation automation activity is the highest today.

We are now expanding into other territories where there is a high activity of critical power EcoXpert partners and which we want to address, also with substation automation certification. Latin-America, Pacific, China, and Europe are undoubtedly interesting markets, and of course, North America isn’t just a huge market but also has many end-users open on working with system integrators.

The substation automation targets two profiles of system integrators: the first one consists of the companies which are specialized in engineering solutions, focused on bringing together substation automation hardware and software to their customers. Then companies that are interested in extending their knowledge to substation automation competencies to complete their business model. These companies are the contractors, panel builders and services providers. Finally, end-users or end customers can also act as system integrators, for their own facilities. The latter one is not addressed with the substation automation EcoXpert certification.

The substation automation EcoXpert certification is still new, so perhaps it’s too soon for cases?

Aimen Abd-el-azim: This certification is indeed new since this year, but as mentioned, the system integrator activity in substation automation was running in a pilot mode for the past three years.

During this period, we’ve had good successes all around the world, that I propose we give our partners the opportunity to talk about it next time. Meanwhile, I would like to mention that some of our partners achieved up to 50 percent of market share in their electrical utilities with full IEC 61850 adherence as they leveraged the edge control layer to meet the changing demands of the utility.

This year we decided to embark substation automation in the EcoXpert program, as it has the entire ecosystem for our system integrators to unleash their full potential and repeat the similar successes in all segments and new geographies.

The new EcoXpert Substation Automation certification

We’ve covered several of the many strengths and benefits of the EcoXpert partner program in previous interviews with your colleagues who are responsible for another certification. Yet, probably not everyone reading this will have read those, so what are the main benefits of joining the substation automation EcoXpert certification program according to you?

Aimen Abd-el-azim: The substation automation EcoXpert program brings an entire ecosystem that contributes to our partners’ achievements in the Substation Automation businesses.

- First, there is the Schneider Electric brand and the EcoStruxure technologies, which are well recognized and appreciated by existing partners and end-users.

- Secondly, with EcoXpert, we have an environment that ensures the partners are adequately trained and certified, providing them with the right level of competencies and qualities that help them succeed in their business with our ongoing support.

- Thirdly, I would emphasize our new Exchange platform that offers our partners all the information and tools, to find a solution to end-users’ needs, learn from our feedback on and additional enablement of their capabilities to thrive by connecting them with Schneider Electric, with other EcoXperts and the end-users.

Exchange also provides them with a whole set of material that makes it possible for them to grow, promote themselves, and gain a competitive advantage.

Last but not the least, EcoXpert partners will benefit from Schneider Electric’s expertise, experience, and tools, enabling them to reduce their engineering effort, helping them to reach the latest compliance requirements whenever required, as it would be for truly cyber secured solutions.

That’s clear. Any last thoughts?

Aimen Abd-el-azim: The new EcoXpert certification for substation automation is here. It was in the making for three years and is launched as a response to the need to support our partners and end-users by offering the required expertise and competencies based upon the substation automation products and software.

And the first successes are here to prove it, which is food for a later article. Thanks, Aimen.

Disclosure: this is a sponsored post in the scope of the commercial collaboration between i-SCOOP and Schneider Electric, containing links to solutions and the partner program of Schneider Electric. All images are property and courtesy of Schneider Electric with the exception of the panel image – ShutterStock copyright guruXOX