IIoT stands for the Industrial Internet of Things or Industrial IoT that initially mainly referred to an industrial framework whereby a large number of devices or machines are connected and synchronized through the use of software tools and third platform technologies in a machine-to-machine and Internet of Things context, later an Industry 4.0 or Industrial Internet context.

Today IIoT is mainly used in the scope of Internet of Things applications outside of the consumer space and enterprise IoT market, as an umbrella term for applications and use cases across several industrial sectors.

The Industrial Internet of Things or IIoT is defined as “machines, computers and people enabling intelligent industrial operations using advanced data analytics for transformational business outcomes”.

Machine-to-machine communication and IIoT

In the pure machine-to-machine and Industry 4.0 context, the advantage of the frameworks and systems that IIoT refers to, is that they can operate semi-independently or with very minimal human intervention.

Such systems will increasingly be able to intelligently respond and even change their course of action based on the information received through the feedback loops established within the framework.

As mentioned a keyword here is machine-to-machine communication (M2M), which is an element of the Internet of Things but also refers to specific activities and to the initial stages of the Industrial Internet of Things.

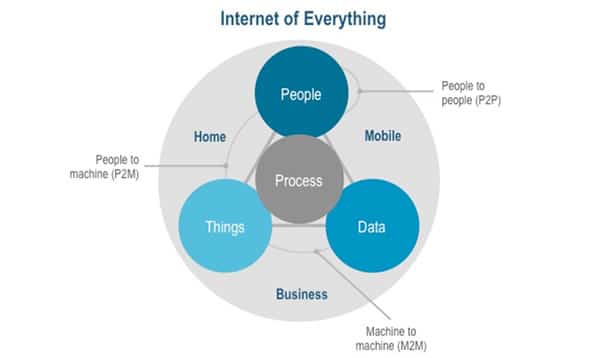

The idea behind machine-to-machine communication is to reduce human interventions as much as possible so that the highest level of automation could be achieved. If we look at the concept of the Internet of Everything, this M2M dimension of the Industrial Internet of Things happens within the sphere of the things as you can see in the original depiction of the Internet of Everything by Cisco.

The IIoT in this sense can be considered a movement towards ‘smart machines’ whereby the accuracy levels of the operations involved in the respective systems are heightened to a level that cannot be achieved through human interventions.

Benefits of IIoT in manufacturing and beyond

One of the greatest benefits of Industrial Internet of Things has to be seen in the reduction of human errors and manual labor, the increase in overall efficiency and the reduction of costs, both in terms of time and money. We also cannot forget the possible underpinnings of IIoT in quality control and maintenance.

The Industrial Internet of Things is part of the Internet of Things.

Internet of Things or IoT is data-rich: large amounts of data get collected, aggregated and shared in a meaningful way. Here again the goal is to increase the automation level at domestic and commercial levels. In the Industrial Internet of Things, data is crucial as well and this causes a change in the human tasks in an Industry 4.0 context whereby automation leads to a decrease of specific types of work but at the same time requires new skillsets.

The goal of the Industrial Internet of Things is also not to fully replace human work, its goal is to enhance and optimize it by, for example, creating new revenue streams and business models with a big role for data (analysis).

The intelligent communication loop setup between machines enables timely attention to maintenance issues. The safety level of the operations is also boosted by alleviating the risk factors.

The Industrial Internet of Things takes the benefits of the Internet of Things in general to a higher level and also to the industries with high-stakes where human error could result in massive risks. The precision level that can be achieved through the IIoT is one of the greatest advantages, that makes this discipline one of the most welcome gifts of IoT.

Times are not far whereby entire manufacturing plant operations and processes could be made to operate almost independently; the so-called lights-out processes. Moreover, the Industrial Internet of Things is used for many use cases which help us reduce the exposure of human workforce, which will always matter, to scenarios with high industrial hazards. In a context of the future of work there is also an increasing focus on ‘human augmentation technologies’.

In the coming years, IIoT is likely to force more unified device protocols and architectures that will allow machines to communicate seamlessly and thereby enhance interoperability.

To summarize, here are some of the key benefits of IIoT in an industry context

- Improved and intelligent connectivity between devices or machines

- Increased efficiency

- Cost savings and

- Time savings

- Enhanced industrial safety

It is certainly a worthwhile space to watch as the developments here bring about the biggest industry revolution of the Internet era but also because most Internet of Things deployments today happen in the Industrial Internet of Things and, specifically in manufacturing and smart factories.

The industries and evolutions in IIoT

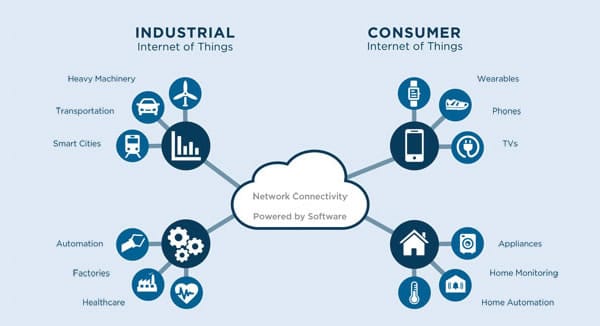

As mentioned there has been a shift from the pure M2M and Industry 4.0 dimension in the Industrial Internet of Things whereby it is used to distinguish between the Internet of Things in the sphere of consumer devices and applications across all sorts of industries where systems and deployments are mission-critical.

Obviously, in the end and in several Industrial Internet of Things applications, for instance in smart metering or smart city projects, the customers can be consumers so both worlds are not completely different.

Major industries include oil and gas, transportation, manufacturing, healthcare and energy but they are certainly not the only ones. Many use cases in government (smart cities) and agriculture, for instance, are also seen as IIoT.

Last but not least it’s important to mention that the focus of the Industrial Internet of Things is increasingly moving from some of the mentioned benefits and other benefits such as cost savings, better automation and productivity gains towards innovation, the development of new business models, services and/or products and even the development of new revenue streams in a world where data is money. In the infographic from the Industrial Internet Consortium below you can find more information (note: the Industrial Internet is not entirely the same as the Industrial Internet of Things but in practice the two terms are used as synonyms).

Top image: Shutterstock – Copyright: Zapp2Photo – All other images are the property of their respective mentioned owners.