How do we find value in Industry 4.0? Fully answering that question would probably take a book with various scenarios and roadmaps, depending on the individual organization. Still, here are some aspects and actions to take we would like to point out in realizing the value in industrial digital transformation.

The question of value is omnipresent in the frameworks and scope of Industry 4.0 and the Industrial Internet of Things. In the end, the very concept of Industry 4.0 (and even its reference architecture framework) is about the full value chain. Yet, as we saw, based upon among others research, industrial markets de facto are still in the first stages of their industry 4.0 transformations.

Looking beyond solutions and to strategic plans

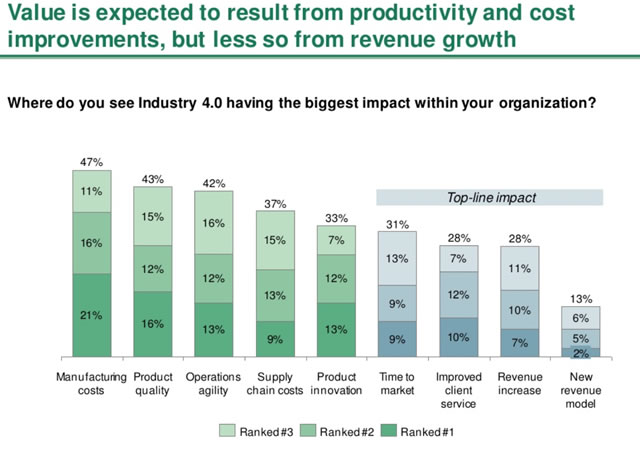

To quote from the research by the Boston Consulting Group which we cover on our Industry 4.0 page: “The value created by Industry 4.0 vastly exceeds the low-single-digit cost savings that many manufacturers pursue today”.

Even if currently many industrial transformation initiatives focus on ad hoc initiatives and low hanging fruit, this doesn’t mean that you can’t create value in those early stages. Yet, the value created is often limited and oriented on cost savings and cost avoidance, whereas the major value sits in higher transformational goals.

Rome wasn’t built in a day, a mature industrial transformation isn’t either. Moreover, we see the exact same realities and challenges regarding the maturity of Industry 4.0 projects and the value they create in digital transformation efforts across any industry (and there is no reason for industrial markets not to look at what happens in other sectors as in the end it’s the end customer that drivers change across the full supply chain and lessons can be learned everywhere).

However, it is time for industrial organizations to get their act together and come up with roadmaps towards a more integrated and value-oriented approach whereby each step enables the next ones.

Just like digital transformation, Industry 4.0 is a journey. That journey has intermediate goals and goals at the end of the road. Yet, at the same time the road doesn’t stop as change is a constant. Compare it with the Industrial Internet of Things as part of a continuous industry information. Still, despite the fact that end goals will change over time, it’s crucial to know where we stand now, where we want to – and need to – go and what we need to get there; obviously with value creation and clear benefits as Key Performance Indicators.

When you walk the trade floor at any industrial event, keep that in mind. Yes, the latest logistics robots and cobots can do amazing things and offer tangible value as ample cases show but look beyond them. How can they fit in a more strategic plan that creates even more value? Indeed, IoT use cases show marvelous possibilities but, looking beyond use cases and the latest IIoT connectivity solutions or IIoT platforms, how can your organization create more value by leveraging the (Industrial) Internet of Things by going beyond the traditional examples of production asset management and maintenance, freight monitoring and manufacturing operations to name a few of the major areas of investment/spending in the Internet of Things? Obviously organizations invest to create, extract and, now and then, protect value. Just look at some of the cases we tackled in our article on cobots.

Doubling production output by deploying a solution from Universal Robots with a payback period of 3 to 6 months. It’s not bad, is it? However, making abstraction of this case and any case in any area of industrial transformation, there is more; there always is when you look beyond optimization and efficiency and especially in this big integrated picture we have ahead of us, encompassing numerous processes, technologies and opportunities. Now, what stands in the way of formulating such a clear plan and roadmap?

Leadership and gaps: the need for a strategic Industry 4.0 and Industrial Internet of Things roadmap

There is no doubt about it: wherever you look, you see the same gaps. A large majority of companies, anywhere in the world, sees that Industry 4.0 and the (Industrial) Internet of Things will 1) affect the manufacturing industry (and others) and 2) be essential for them.

Yet, at the same time they feel uncertain, are underprepared, aren’t really sure if they grasp the benefits and face a range of stumbling blocks that make it hard to take action. This is a classic but it’s time to solve it.

Industrial transformation is a journey and has no real end but it needs to be driven by the end goals as we can strategically envision and plan to achieve them

Remember that big integrated opportunity we just mentioned and we’re pretty sure that’s what the core themes of value and integrated industry of Hannover Messe 2017 were about too: it’s a vast given and we have an inevitable tendency to focus on leveraging and seeing the opportunities in what we know. Indeed, that optimization and automation part of the equation. It’s in the part that we might not see yet where the real value lies. There is no universal rule that says that there is more value in the less obvious and more difficult than in the obvious and low hanging fruit or immediate needs (which of course need to be tackled) but in a transformational context there truly is. And it’s why we need to be more strategic and work around scenarios, involving experts and customers and so on. The first step to get that done is a clear and informed vision for the future that looks at this vast integrated potential. That is a task for leadership.

If you look at successful digital transformation strategies you see that leadership needs to be involved and even take the lead as the changes are so fundamental for the organization (there are exceptions in practice, albeit often in specific projects).

Moreover, several ‘less typical’ stakeholders are involved on a leadership level (on top of the existing ones) as the core assets of the digital transformation economy AND of Industry 4.0 revolve more about ‘business assets’ you don’t see on the balance sheet but really are business assets: actionable data, partnerships and ecosystems of value, innovation capacity, customers, agility, trust and security, you can go on.

The role of leadership is to:

- Enable solving current needs and short term goals without being blinded by them

- Co-develop a strategic view and vision and get the right people around the table to do so

- Envision that bigger picture and plan for it, clearly formulating the vision and the gaps that need to be filled

- Build ecosystems of value and information where in the ‘as-a-service’ tranformation of Industry 4.0 lies the key to value

- Revisit the core assets of their organization and enable the development of innovative capabilities and maturity with regards to customer-centricity, big data analytics and agility

- Foster a culture of continuous innovation and transformation – to create and detect value in areas beyond the immediate

- Have a clear actionable roadmap to move higher in the value chain of true and have a staged transformation action plan

- Challenge the status quo and immediately visible gains by emphasizing the strategic skills that are needed today for tomorrow, on top of the other skill sets that will be needed to turn vision and plan into reality and value.

It’s the role of leadership to understand the changes that are afoot and set in motion the formulation of a strategic approach. All industrial markets are evolving in a platform economy with a key place for ‘as-a-service models’. It’s the role of leadership to see how ecosystems of value and of information are essential amidst these and other changes we’ll touch upon in a next article. It’s the role of leadership to enable innovative capabilities as mentioned in our digital transformation guide. And it’s the role of leadership to – collaboratively – identify the partnerships and sustainable models that enable the creation and extraction of maximum value in Industry 4.0.

Forward-thinking industrial leaders have adopted a culture of continuous optimization, transformation and innovation, they use test beds and set up pilots, they have a staged approach, they work from project to project to end goals, they work much more in collaboration with customers, they leverage analytics, they have a strategic roadmap without ignoring the bigger picture and they actively engage and build ecosystems and communities of creatives, young developers, customers, innovators, peers and so forth in an ecosystem view

Obviously this all sounds easy but whether it concerns Industry 4.0 or any ‘new’ evolution that impacts organizations profoundly it’s key to keep those essential questions and steps of optimizing, innovating and transforming with ‘normal’ business goals in mind. They key of success lies in understanding and involving the new ways and ecosystems to get there. That is part of the strategic plan, which as any strategic plan maps out where you want to go, assesses where you stand, analyzes the gaps and stumbling blocks and sets out a plan that needs to be rolled out and obviously monitored.

Unfortunately most industrial companies aren’t there yet at all and strategic initiatives focus predominantly of the classic goals of optimization.

In a next article we diver deeper into the challenges, realities and steps and present a more tangible and precise strategic overview of the industrial transformation and Industry 4.0 steps to take and challenges to tackle.

Top image: Shutterstock – Copyright: Panchenko Vladimir – All other images are the property of their respective mentioned owners.