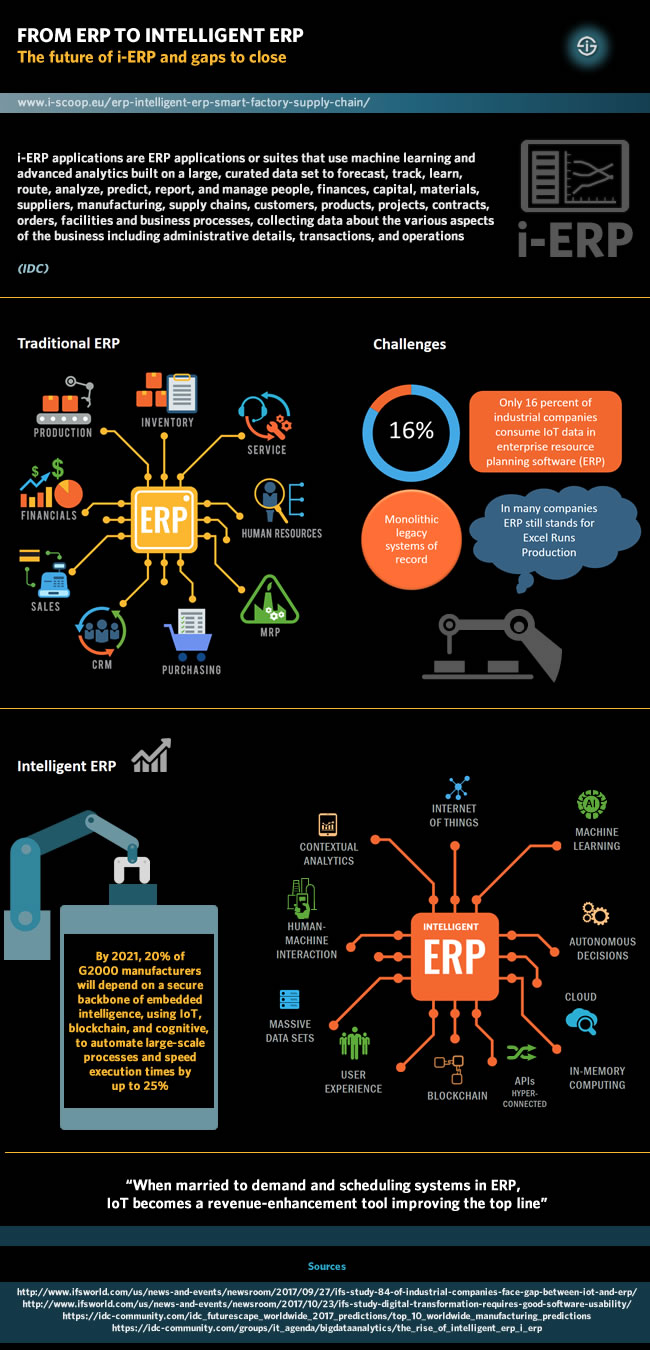

ERP (Enterprise Resource Planning) as a monolithic systems of record is disappearing and making place for Intelligent ERP or i-ERP where actions and intelligence matter. Intelligent ERP comes with a mix of artificial intelligence and machine learning, blockchain technology, massive data sets, a focus on user experience, cloud and the Internet of Things.

The industrial transformation of Industry 4.0 and the Industrial Internet, with its increasing role of IIoT, advanced data analytics and vertical and horizontal integration profoundly impacts various systems in manufacturing.

The role of the manufacturing execution system (MES) is evolving and so is that of ERP (Enterprise Resource Planning). In this article we take a look at the evolutions in ERP and more specifically the rise and place of intelligent ERP or i-ERP as research firm IDC called it. However, at the same time we look at the reality of ERP as it exists in manufacturing today as well. It shows that there is quite some work to do before that intelligent ERP will run your smart factory and supply chain management business processes.

In a sense intelligent ERP is already here and many vendors such as SAP and Microsoft, to name two, already jumped on board of the i-ERP train. Moreover, IDC is very bullish on the role, importance and forecasts with regards to intelligent ERP which, among others, need to be seen in the broader context of the movement towards more intelligent business platforms and has been called the new backbone for digital transformation by the company. Do note that intelligent ERP is not just for the manufacturing industry but it’s in this scope that we look at it.

Intelligent ERP in the context of ongoing convergence and Industry 4.0

First a bit of background. The broad landscape of systems which are used in manufacturing is in full flux overall. With, among others the advent of IoT and the Industry 4.0 frameworks, the traditional automation pyramid is not even a pyramid anymore.

The cloud, edge computing, network evolutions, industrial IoT, machine learning, connectivity and linking between the various systems on the field level, control level, production level, operations level (MES and MOM) and enterprise planning level (where ERP and intelligent ERP come in) becomes far more important.

The same applies for the interfacing between these core systems and the various Level 3 and Level 4 systems of ISA-95, from warehouse management systems to CRM.

Against this background of increasing connectivity which essentially revolves around the vertical and horizontal integration of Industry 4.0 (where the pyramid view still comes in but really needs to be revisited), the industrial IoT and other evolutions, the face, role and place of ERP is changing as is that of manufacturing execution systems. The rise of the intelligent ERP system can be seen in this context of hyper-connected business with, in manufacturing and smart supply chain management, ongoing automation and the movement towards semi-autonomous and autonomous decisions. Artificial intelligence, machine learning, advanced analytics and IoT indeed.

However, intelligent ERP also needs to be seen in the broader perspective of what organizations expect from today’s business solutions overall. And here there are lessons to be learned from what has happened the past years in the overall IT landscape.

The shift from systems of record to systems of engagement, intelligence and ultimately systems of decisions

The shift away from systems of record and even of systems of engagement is an evolution we have tackled several times before in the context of information management.

And what else are we doing in industrial transformation than putting information and the decisions/actions derived from it at work in an increasingly autonomous ways, while unlocking the full value of information that comes from ever more sources and in ever more formats? It’s the reason why at the core Industry 4.0 is so data-intensive to begin with.

Yet, when it boils down to ERP we are often still stuck in the systems of record reality with legacy systems that aren’t exactly built for easy integration and slow down digital transformation. Worse, there is still quite a lot of manual data entry going on, certainly when the layer between the enterprise planning level and the production level of industrial control systems and SCADA system (where the MES sits) is lacking and, as we’ll see ERP still stands for Excel Runs Production (let’s not talk about paper-based processes).

There isn’t a lot of intelligent ERP and integration of IoT, massive data analytics, cognitive and process automation, let alone autonomous processes and decisions, going on yet.

By way of an example: even if IFS is a connected service management solution provider, the findings in a September 2017 study from the company that 84 percent of industrial companies face a gap between IoT and ERP aren’t surprising at all. Knowing that IoT is the main driver in the overall digital transformation of manufacturing, that shows we’re not in an intelligent ERP environment yet, to say the least as intelligent ERP almost by definitions needs IoT data and analytics. Quoting IFS CTO for North America, Rick Veague: “Are your planning and maintenance systems robust enough to make real time decisions using IoT-sourced data? Many are facing the reality of having to answer ‘no.’ We have seen examples of companies coming to us because their incumbent software is not able to administer and use IoT data to achieve the gains they want to realize.”

Intelligent ERP and the shift towards the user of applications

In our article on digital transformation and information and in the mentioned article on information management we explain how digital transformation is, among others, about 1) information, 2) people, 3) experiences, 4) speed/timing, 5) convenience, 6) processes/automation and 7) interconnectedness/collaboration.

The role of the customer experience and of user experience can’t be underestimated in any system or application nowadays. As written before in an article on the disruption of enterprise content management, gaining user adoption remains a big challenge in this space, just as it does in so many others.

Moreover, gone are the days that IT decided on a system and users simply had to use it. Today’s worker expects the same ease of us from enterprise applications as he does from any other solution out there. It needs to be intuitive, easy and user-centric or it simply won’t be used at all.

However, in ERP and several other systems in the manufacturing environment this is not the case. So, it doesn’t really come as a surprise that intelligent ERP takes that user experience into account and even puts it front and center, in combination with a mobile-first approach and soon the new types of interfaces enabling to interact with these systems as we’ll cover further (think, among others, NLP or Natural Language Processing as part of the enabling mix). You can compare this with digital twin evolutions whereby we see that digital twins are equipped with different interfaces, also leveraging NLP, to engage with the system.

How is that focus on user experience in ERP and other systems in manufacturing today? Again we point to research from IFS, keeping into account that the company is a vendor: in October 2017 IFS released the results of a study that in a sense states the obvious in its title (‘Digital transformation requires good software usability‘) but does offer some undeniable truths in its details.

The survey was conducted among 200 industrial users of ERP, FSM (field service management) and EAM (enterprise asset management). Among the conclusions: “in many companies, ERP still stands for Excel Runs Production”. A whopping 88 percent of respondents would abandon enterprise software for disconnected spreadsheets, defeating the purpose of an enterprise application, when confronted with poor software usability.

The smart factory and smart supply chain need speed, seamless processes and a focus on outcomes

Here we combine some highly inter-connected evolutions, that lead to the need for intelligent ERP and are pretty ubiquitous in other areas too.

Speed has not just become a business differentiator it is also key in the smart factory and smart supply chain. If a system is hard to use as just mentioned and if it’s prone to errors because of manual data entry it slows everything down.

Moreover, without advanced automation and the ability to turn data into outcomes and next actions in processes in the line of business, there is no room for the speed and the outcomes that LOB staff, executives and the overall manufacturing ecosystem nowadays want.

This can also be perfectly be compared with various other areas such as document capture where the need to speed up processes, reduce manual labor and errors, and move faster from one step in the overall process to the others has led to an ongoing focus on ways to capture data as close as possible to the source, to the line of business, the knowledge worker and so forth. It’s at the core of evolutions with regards to business process optimization and even of the evolutions in document imaging.

Same thing with intelligent ERP and with similar benefits on top of speed and the others we mentioned, including lower costs, more satisfied LOB executives and knowledge workers (who are fed up to wait for IT, let alone with wasting time to do their job) and an increased overall agility, one of the key capabilities enabling hyper-awareness and hyper-responsiveness in digital transformation.

Intelligent ERP as a system of integration – connecting with other applications for advanced end-to-end business process automation

There is a lot more to be said about intelligent ERP drivers and comparisons with evolutions in other areas. Simply put you can see the intelligent ERP on the most basic level as the ERP becoming a system of engagement, system of insight and intelligence, system of decisions and system of integration and connectivity instead of just a system of records.

And that has multiple consequences on multiple levels. As ERP applications fulfil so many tasks in business process optimization in areas such as order management and processing, in data collection, in planning on an enterprise production level, in BPM overall and in hooking up with other systems (HR, invoice processing and accounting, shipping, warehouse management, CRM, materials management, procurement and supplier management and so on), the far-reaching possibilities of intelligent ERP become all the more clear and vast.

This is especially so if we add that inherent technological dimension of ‘intelligence’ to it which, among others, refers to components such as predictive analytics, machine learning and autonomous decisions and actions (also on the level of connected processes such as paying invoices, ordering materials or taking shipments decisions based upon multiple sources and huge amounts of contextual fast data, analyzed and leveraged in real-time with AI and self-learning components).

The state and future of intelligent ERP as the Industry 4.0 autonomous decision center on the business process level

Intelligent ERP is really the ERP that matches with the autonomous decision vision of Industry 4.0 and Logistics 4.0 but then on the business process level.

Next gen technologies and the future of intelligent ERP

The technological dimension is baked into the very definition of intelligent ERP.

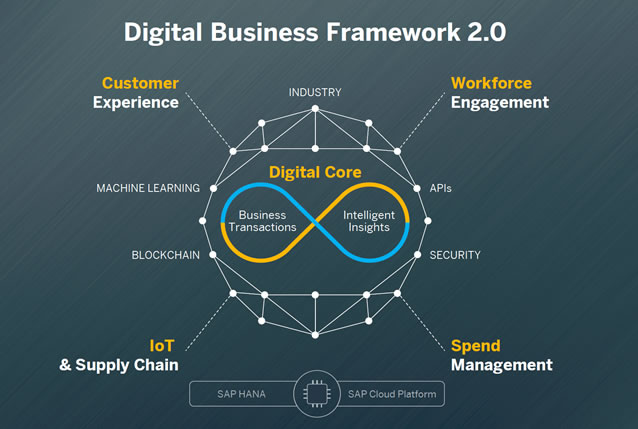

When SAP announced the advances and innovation roadmap for its next gen ERP suite in February 2017 the company clearly referred to contextual analytics, digital assistant capabilities, machine learning and its SAP Fiori user experience, as mentioned all aspects of intelligent ERP.

As stated in our recent article on manufacturing sector and manufacturing technology evolutions in convergence with manufacturing predictions for 2018 and beyond, IDC expects that by 2021, a fifth of the Global 2000 manufacturers will depend on a secure backbone of embedded intelligence, using IoT, blockchain and cognitive (artificial intelligence and machine learning) to automate large-scale processes and speed up execution times by up to 25 percent. That is what we are talking about here as for IDC in many organizations this will happen through that intelligent ERP system. IDC has been leading the debate on next generation ERP and coined the terms i-ERP and intelligent ERP as you can read in this overview.

However, if the intelligent ERP will integrate IoT, blockchain and cognitive in what IDC calls embedded intelligence to realize those automated large-scale processes with advanced technologies, there is still quite a road ahead for many vendors and buyers if we keep in mind those IFS findings on the user experience of, among others, ERP systems, that ongoing “Excel Runs Production” challenge and that gap between just IoT and ERP that exists end 2017 and will not be closed in 2018.

It’s probably the reason why embedded intelligence and the intelligent ERP in the context of the mentioned prediction is one for the longer time, not in the least because there is still a long road ahead and it does demand quite some evolutions and changes.

Blockchain, cognitive, IoT and intelligent ERP

For many blockchain isn’t even really understood or known yet. With regards to the actual usage of AI and IoT in the smart factory and Logistics 4.0 the same can be said from an adoption perspective and most certainly from a use case perspective and the reasons why manufacturers today use IoT or AI, if it all.

And then we haven’t even mentioned the next gen “assistive and collaborative conversational styles” user experience interfaces with natural language processing yet, which are also part of the core of intelligent ERP.

Keeping into account that the prediction is also for the top manufacturers and that for many it’s still soon for blockchain, it’s clear that intelligent ERP or i-ERP or whatever the name will be, is coming.

SAP has it on the mentioned roadmap for future cloud ERP innovation and “detailed plans for including blockchain digital ledger capabilities and Internet of Things capabilities that will support broader global, digital business models, as well as plans for partners to build localization and industry vertical extensions”.

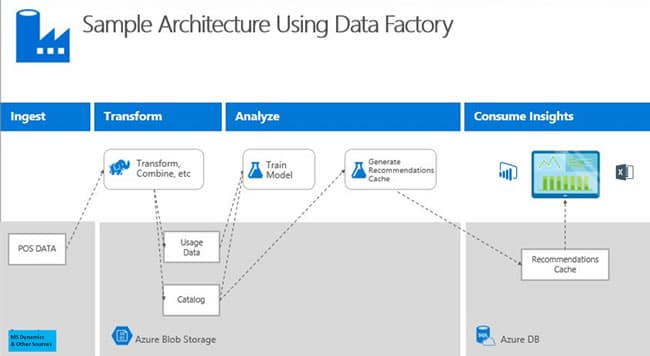

Microsoft, for now, mainly looks at the usage of data and analytics to improve business process and operations, with a focus on Microsoft IoT integration, machine learning, the Cortana Intelligence Suite, Azure Data Factory, Dynamics 365 and so forth.

It’s wait and see but of course also prepare and learn because intelligent ERP is coming but so is more cognitive and blockchain, already reason enough to take a good look what these technologies do and can do in manufacturing and in combination with IoT and so forth.

Top image: Shutterstock – Copyright: NicoElNino – ERP image in infographic: Shutterstock – Copyright: ananaline – All other images are the property of their respective mentioned owners.