In an interview on the state and evolutions of critical power buildings in this connected day and age we looked at the impact of the IoT and how pervasive metering offers an enormous opportunity to track the usage of energy, both from a quantity and quality perspective. In this post we look at energy efficiency in the critical power building environments of Industry 4.0.

Critical power buildings encompass facilities such as hospitals, data centers, airports and essentially any building where the availability and reliability of electricity is crucial and an interruption or diminished quality would lead to serious consequences. As we know from research on IoT investments, buildings and facilities are among the main IoT use cases for several years to come and this also goes for critical power buildings. The automation of airport facilities, for instance, is the IoT use case with the fastest growth in spending until 2021 (33.4%).

The consequences of power disturbances/blackouts or poor quality power impact critical power buildings on the level of business continuity, costs, safety or all of these – and more – factors combined, as Kevin Morin, responsible for the EcoXpert partner program critical power certification badge, explained.

Industry 4.0 and power management – more than a matter of energy efficiency, costs and continuity

In the development of Industry 4.0, energy management and energy efficiency overall has taken center stage. As a matter of fact, knowing sustainability regulations, specific power needs and increasing importance of energy to drive the smart factory and smart industry, there is more attention than ever for energy efficiency in industrial markets.

It’s not exactly a secret that factories and many other industrial facilities are not just among the main “consumers” of power but that power is equally critical in ensuring continuity and quality of the end-to-end manufacturing process. There is a reason why in Industry 4.0 there is so much attention for topics such as maintenance and asset management. There is also a reason why suppliers of industrial robots such as ABB Robotics are among the first to have built IoT-enabled connected services to enhance maintenance and minimize disruptions with regards to industrial robots in a market where every second counts and downtimes need to be avoided.

Just as an unexpected failure in a critical component in the manufacturing process of, for instance a large car manufacturer, results in enormous costs, so do issues with regards to electricity and power.

Obviously, the benefits of large IoT projects such as the mentioned one by ABB Robotics go beyond continuity and maximal uptime. Cost savings are certainly among them, for instance with regards to interventions by field service reps.

Why energy efficiency is an inherent component of Industry 4.0

With regards to power management and energy efficiency in Industry 4.0, staying within the context of factories and facilities and not the broader Energy 4.0 picture (which is essential too nevertheless), there is more than just the sheer need for power availability, reliability, quality and manageability.

Driven by a mix of environmental factors, cost challenges, regulations and so forth the attention for pro-active energy consumption capabilities (which is partially about regulations) and for the integration of alternative sources of energy has never been higher and is even poised to increase.

Kevin Morin referred to it in the mentioned interview on IoT and critical power buildings. Quote: “Over time, as energy becomes an increasingly digital given with sensors, while also becoming more decentralized with energy coming from a local solar photovoltaic, wind or microgrid system, users will have even more control and ability to manage their energy usage”.

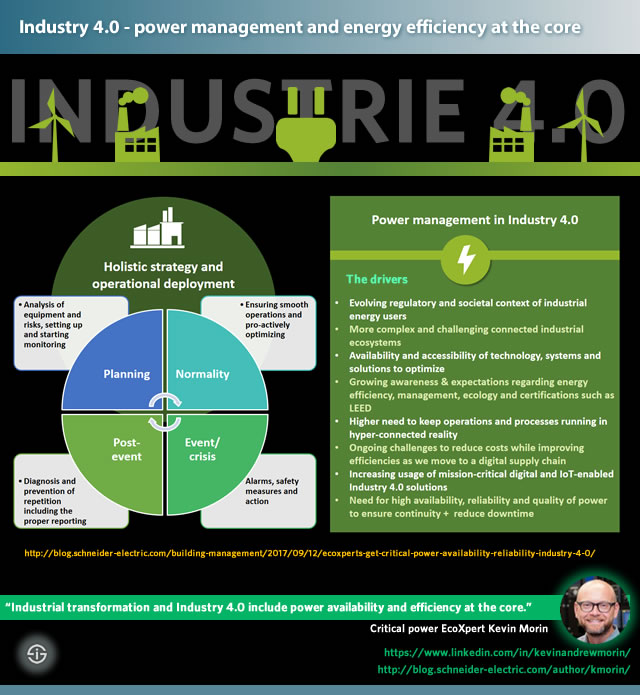

Power availability and reliability are not just important for critical power buildings, manufacturing processes and all the other mission-critical operations in the scope of Industry 4.0: as Kevin Morin writes in his blog post on “Critical power availability and reliability in Industry 4.0“, power management, energy efficiency and power availability are an essential part of Industry 4.0. Putting it another way: without power management and energy management overall at the center of Industry 4.0 there is no Industry 4.0.

Kevin sees several drivers of the fact that power availability and energy efficiency in the broadest sense are high on the priority list and in the capital projects of industrial energy users as he puts it. We’ve mentioned a few of them and summarize them in the illustration below.

Knowing the challenges, drivers, realities and, inevitably the technological components and evolutions, including IoT, data analytics and so forth is one thing, acting upon it another.

Top image: Shutterstock – Copyright: everything possible – All other images are the property of their respective mentioned owners.