Our last article on MES (manufacturing execution systems) mentioned how MES systems, functions, and data started moving to the cloud.

With some industries going for cloud MES faster, cloud computing was expected to be one of the growth drivers of MES usage, along with digital transformation, IIoT, and more integrated ways to leverage connected data, including advanced data and analytics platforms.

A few years later, we see that cloud adoption for MES (and MOM) is accelerating, albeit slower than some other categories of software used in manufacturing (e.g., ERP), while manufacturing technologies continue to converge.

One of the key drivers in the increasing adoption of cloud MES is the desire of companies to enhance business and operations through better-integrated systems offering connected data and insights. Removing traditional silos (as the cloud, IoT, and Industry 4.0 technologies allow) enables new opportunities and offers complete visibility and control in operations.

This demand for more integrated systems (and more integrations with other applications) isn’t new, happened in other areas before IoT existed, and drives changes in other areas, such as building automation and energy management.

End clients look at their business and see what is needed to succeed – but when they look at the solutions needed to make it happen, they see silos and islands of technologies and solutions which they want to connect.

Cloud and MES: integrations on all levels as silos disappear and new technologies become more important

While cloud MES usage is on the rise, and edge computing has entered the market (for important data requiring the benefits edge offers), the cloud has a broader role in ever more integrations.

The evolution towards cloud MES and other manufacturing applications in the cloud goes hand in hand with the cloud’s inherent benefits in having a scalable infrastructure that enables to get the most out of connected data and rapidly realize integrations fast. It is also linked to the changes in the cloud market and the market of IoT platforms and other applications used in smart manufacturing.

The capabilities of IoT platforms have grown a lot in recent years. As a result, buyers now dispose of (and demand) integration possibilities between IoT platforms, MES systems, and sometimes even applications we hardly talked about in the past. At the same time, the lines between MES and ERP systems continue to blur with overlapping possibilities between these (and other) categories of applications.

Last but not least, we see more integrations taking place between cloud and other technologies. As mentioned in a recent article on public cloud spending, Gartner expects more investments for complex and novel public cloud use cases whereby the usage/adoption of cloud computing and services is combined with IoT, 5G, AI, and other technologies.

“The capabilities of key manufacturing software tools are overlapping more and more. This is particularly apparent for the interfaces of ERP systems and MES systems as well as IoT Platforms and MES systems, especially when hosted in the cloud” (IoT Analytics)

In the context of MES (and cloud), the integration of AI tools, IoT systems, and certainly also digital twin possibilities are worth mentioning. Cloud MES adoption also means that the convergence of software tools, the increasing integration of AI tools, and the increasing integration of digital twin capabilities will be accelerated.

The fact that integration is vital beyond the plant level shows in the solutions and strategies of vendors, whereby integration of the MES in the entire business is the goal.

MES cloud deployments: fast growth for SaaS with a focus on SMEs; most deployments private cloud-based ‘lift and shift’ migrations

Many organizations today opt for a hybrid cloud MES approach. According to a survey by IoT Analytics, a German IoT research company, investments in SaaS MES cloud architectures are expected to grow fastest.

As often with cloud-native SaaS applications (Software as a Service), this will mainly be the case for small and medium companies that don’t want to invest too much upfront, have limited IT infrastructure, and want to start, integrate and scale fast.

Larger organizations with a global footprint and multiple plants will mainly move existing on-premise manufacturing execution systems to an off-premise cloud infrastructure (private, public, hybrid).

De facto, most MES cloud deployments will be private cloud-based ‘lift and shift’ migrations with the well-known rationale of users to retain the complete control and ownership of infrastructure, data, and operations.

Yet, as the IoT platform market, dominated by large hyperscalers, and several vertical players continue to offer more integrations between different systems to meet end-user demand, this might gradually change. It’s also clear that the market won’t sit still, and demand for more integrated systems will remain. Last but not least, the importance/impact of edge and new technologies such as 5G should be taken into account.

But one shouldn’t expect miracles, and the shift of manufacturing software, certainly of critical and operational data, won’t happen as it has in some other areas. Per IoT Analytics, business and shopfloor software that are non-critical and non-real-time will lead the migration.

IoT Analytics expects that the main criteria to decide the precise cloud MES approach will be traditional ones such as cost (capital investment, operational expenses), scalability, and data ownership. While organizations might have become more used to working with SaaS and the public cloud and more mission-critical workloads go to the public cloud in general, these evolutions might be much slower with cloud MES evolutions.

“With a hybrid on-premise/cloud Manufacturing Execution System (MES), operations happen on premise, and analytics and optimization tools are applied only to the required subset of the data in the cloud. This is an excellent use of the cloud because it does not pose risk to production yet utilizes the cloud to help reduce the hardware footprint” (Matt Wells, GE Digital)

After all, only a few years ago, not many manufacturers believed they would ever embrace the cloud for MES, let alone move operational data to the cloud.

For a MES provider like GE Digital, a hybrid on-premise/cloud Manufacturing Execution System (MES) is the best way to go, as you can read here. But GE Digital is typically one of those vendors working with large manufacturers, as the case they mention (CPG manufacturer Procter & Gamble) clearly shows.

So, exciting evolutions to watch as the integrations between various solutions for manufacturers, the role of large hyperscalers, and technological changes on the horizon will impact the market.

MOM and MES migration to the cloud: an accelerating market with blurring lines between applications

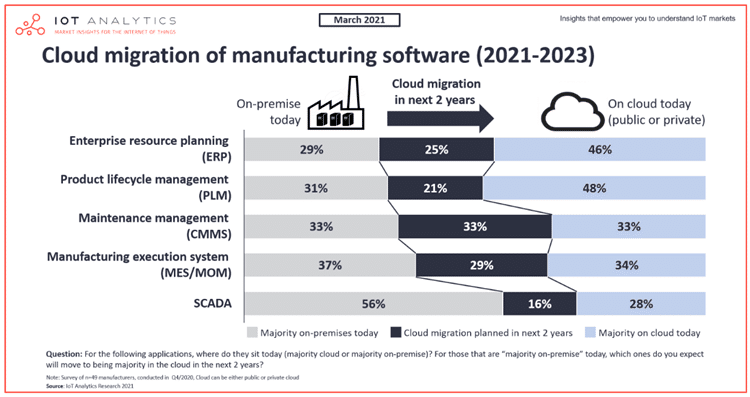

The MES/MOM cloud market is smaller than that of cloud ERP, but as IoT Analytics states, it’s accelerating. According to the market research company, in March 2021, around 34 percent of responding manufacturers have most of their MES/MOM capabilities on the cloud (public, private, hybrid).

“Roughly one-third of MES/MOM and CMMS solutions are already partially deployed in either a private or public cloud environment. 29% of respondents, for example, plan to move their manufacturing execution system (or a large part thereof) to the cloud in the next two years”

However, 29 percent expects a migration to the cloud in the next two years. As a result, the market of cloud MES would reach $2.34 billion by 2026 per IoT Analytics (PDF opens).

On top of increasing digitization efforts in several manufacturing segments as a result of the COVID-19 pandemic, growth of the cloud MES market can be explained by the mentioned evolutions in the market and the growing need to leverage data in a way that creates value but whereby existing traditional systems can’t handle the volume and variety of generated data.

“Shopfloor-level control logic operations will take longer to move to the cloud due to gaps in realizing ultra-low latency communication with high reliability; however, new developments in 5G and wireless communication will likely address these concerns and open the door to even more manufacturing workloads, eventually migrating to the cloud in the coming decade”

Furthermore, the increasing integration of AI tools, digital twin capabilities, and the mentioned convergence of manufacturing software tools continues to play a role. One example of how IoT platform and MES platform functionalities started to overlap is the ability of MES systems to handle IoT data in manufacturing. Cloud MES penetration is set to increase, with the cloud Manufacturing Execution Systems market growing fast as the combination with technologies like artificial intelligence and digital twins will make the cloud an indispensable tool for improving manufacturing operations.

More information and findings in the PDF announcing the survey results and research and in the report, “Cloud MES Market Report 2021-2026”.