Chief supply chain officers are and will continue to be instrumental in the shift from a linear to a circular economy. By 2029, circular economies are expected to replace linear economies, and that comes with consequences for supply chain leaders.

Consumers increasingly want organizations to focus more on sustainability, the reduction of waste, green energy, and environment-friendly initiatives and transformations. Companies in ample industries feel the changing demands for quite some time and especially younger generations expect far more in this regard.

With apologies for the generational cohort generalization, especially Gen Z is more and more conscious of what’s going on with the environment, the many problems with the ways we consume and the damage that is done. They – and others as well obviously, remember the generalization – are the new customers that drive the agenda, forcing organizations to change.

With new regulations, those changing consumer attitudes, economic considerations and – thus – shifting demands from business owners and shareholders towards sustainability, Gartner recommends that chief supply chain officers (CSCOs) get ready for the transformation from a linear to a circular economy.

According to the research company, circular economies will replace linear ones within the next ten years, leading to the statement that by 2029, the circular economy will be the only economy.

84% of participants in Gartner’s recent Supply Chain and the Circular Economy Survey stated that the supply chain has, or will have, decision-making authority when it comes to their organization’s circular economy strategies and initiatives

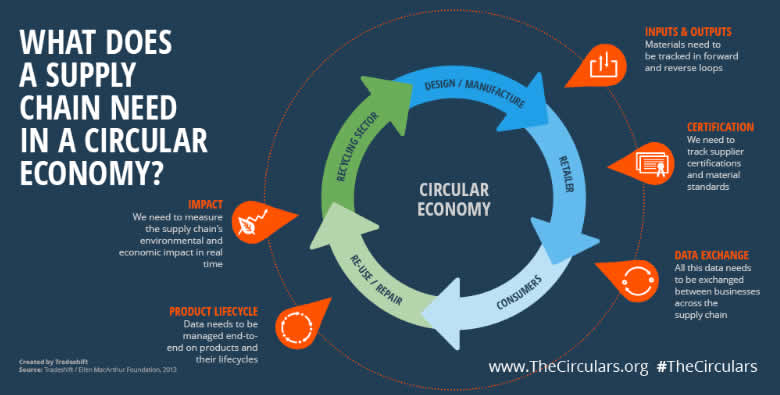

In order to enable a circular economy, automation, the digital supply chain and the essence of the Industry 4.0 model (end-to-end information exchanges across the full chain and ecosystems, vertical and horizontal), along with ample technologies such as digital twins (and digital supply chain twins), AI and IoT, are important. So, moving from a linear to a circular economy isn’t just a transformation; it’s a digital transformation as well.

The supply chain is key in moving towards a waste-free and circular economy: the journey ahead

Back to the chief supply chain officers and the shift from linear to circular economy.

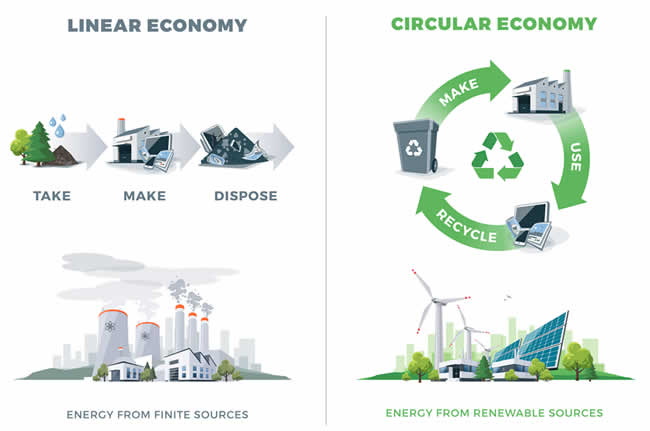

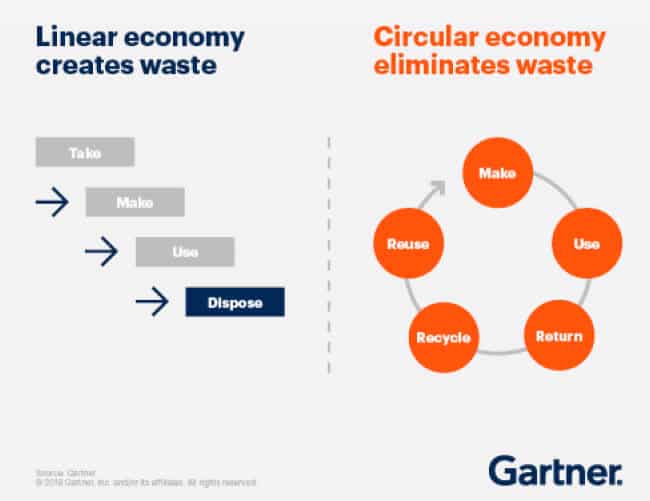

You probably already know what a circular economy but just in case, the Gartner definition goes as follows: “The circular economy is an economic model that separates the ability to achieve economic growth from the consumption of natural resources. Circular economic business models encourage continuous reuse of materials to minimize waste and the demand for additional natural resource consumption”.

A circular economy is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems (Ellen MacArthur Foundation)

In shifting towards a circular and waste-free economy, the supply chain plays a key role, Gartner’s Steven Steutermann emphasizes. This is confirmed in Gartner’s Supply Chain and the Circular Economy Survey in which 84 percent of participants stated that the supply chain has or will have decision-making authority when it comes to their organization’s circular economy strategies and initiatives.

Organizations can’t evolve towards a circular economic model by themselves. It’s an ecosystem play that encompasses the whole chain and all stakeholders.

As a consequence and given the many aspects that need to be tackled, transforming from a linear to a circular economy is a transformation that takes time, collaboration, a clear strategy, a holistic view whereby many questions are to be answered and pieces to be connected (progressively; starting with the simple ones), and metrics to gauge progress and success.

Steven Steutermann, who’s responsible for the Gartner Supply Chain practice as Managing VP, emphasizes that ten years (2019-2029, the year circular economies are expected to take over) isn’t exactly a long time to turn around a supply chain system so since the supply chain is key in that shift from linear to circular economy, CSCOs should start now.

And starting in this case means the deployment of change management programs (which obviously need to be prepared with and within the ecosystem) and starting pilots. The latter should provide the learnings needed for more circular economy initiatives and help in building momentum as pilots tend to do.

In preparing the strategies, change management projects, and so forth Gartner recommends CSCOs to work with their partners such as suppliers but also with internal product designers so they can understand how exactly products are consumed and disposed of after consumption.

Whereas the linear economy model has a ‘Take -> Make -> Use -> Dispose’ approach, in the circular economy the ‘Take’ becomes a ‘Reuse’ and the ‘Dispose’ a ‘Return’ and ‘Recycle’ (in order to Reuse and, from there, ‘Make’, indeed) per the Gartner graphic below. There are variations on the same theme that simplify it even more, yet simple isn’t exactly an appropriate term in shifting towards a circular economy.

Circular economy and ecosystems – starting simple, moving to intelligent collaboration

On top of ecosystems around the organization and the broader chain it resides in, there are also consortia and alliances in ample fields where intelligent ecosystems can take shape.

Organizations are under pressure to reduce the amount of waste they’re producing — from consumers and governments alike (Steven Steutermann, Gartner)

Gartner mentions some examples of such circular economy alliances:

- Make Fashion Circular (by the Ellen MacArthur Foundation, as you know very active in the circular economy which it defines as an economy that is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems);

- The Alliance to End Plastic Waste (already over 40 large, mainly global, organizations) and

- Loop (a global circular shopping platform designed to eliminate the idea of waste by transforming the products and packaging of everyday items in partnership with major brands and retailers).

Steven Steutermann: “Getting together with like-minded professionals will support CSCOs to sketch out a vision for an intelligent ecosystem of partners and peers. They should start with a single question, such as ‘How can I reduce packaging?’, and expand from there.”

So, while transforming into a circular economy isn’t simple, the complex journey starts with simple questions as most large initiatives really should do. It’s also here that this input on how products are consumed and disposed of after consumption is key and needs to be mapped across the entire chain.

Metrics on sustainability do not equal metrics for the circular economy

While the call for sustainability is louder and more evident than ever and the circular economy and zero waste ideal are omnipresent nowadays, organizations have questions concerning the financial perspective and impact of it all.

So, on top of metrics to gauge progress and success, one also need metrics to estimate how changes might impact the business and, among others, consumer preferences and ultimately margins (shareholders expect a lot as well).

Moreover, how do you define metrics for these circular economy efforts, to begin with? Setting measurable goals seems to be the key challenge for supply chain professionals too, as the mentioned survey shows.

In that sense, one needs to be vigilant that metrics on sustainability aren’t confused with metrics that are suited for a circular economy. Steven Steutermann explains: “While some metrics on sustainability already exist, they are mostly related to linear metrics, such as reducing waste to landfills or carbon dioxide emissions. It is important not to confuse those metrics with the circular economy. Good metrics for the circular economy could be the percentages of reclaimed, reused materials for production and the reduction of single-use plastic”.

Reclaiming and reusing what can be reclaimed and reused. And reducing what should be reduced as changes are needed – and insisted upon by today’s and tomorrow’s consumer. Those seem like good categories to develop metrics around indeed.

Here is the link to the research again in case you missed it earlier: “Preparing for 2029, When Consumer Product Supply Chains Cannot Produce Waste.“

Top image: Shutterstock – Copyright: petovarga – All other images are the property of their respective mentioned owners.