Smart manufacturing has been defined as the fully-integrated, collaborative manufacturing systems that respond in real time to meet changing demands and conditions in the smart factory, the supply network, and customer needs.

Smart industry is a synonym for Industry 4.0 or industrial transformation in the fourth industrial revolution within which smart manufacturing de facto fits.

Also known as Industry 4.0 or industrial IoT, smart manufacturing enables manufactures to maximize the yield from existing production capabilities and develop the next generation of production capabilities necessary to compete in a digital economy (IDC)

Industry, the manufacturing business, manufacturing companies and manufacturing processes are in full transformation.

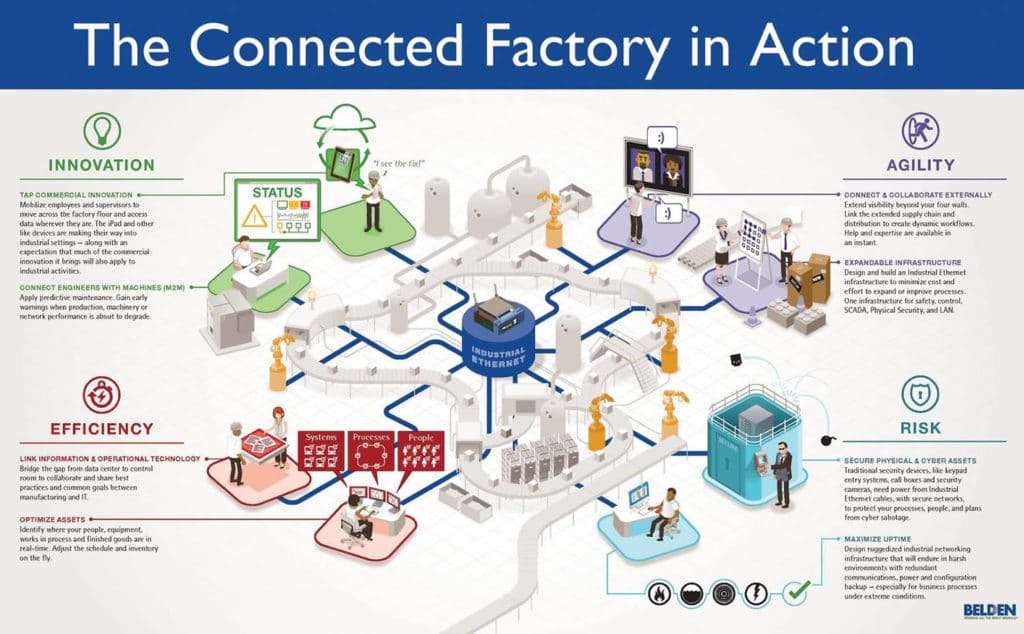

This is mainly due to increasing automation, digital transformation, the bridging of digital and physical environments (as enabled by the Internet of Things or IoT), evolving industrial and manufacturing technologies (such as additive manufacturing), the intensive usage of data/analytics (with cloud and a shift of intelligence to the edge), industry and manufacturing challenges, human, economic and societal evolutions and demands and the integration of information technology and operational technology (IT and OT).

On this page we look at the context of various evolutions and transformations in the industry and in the manufacturing business, across manufacturing processes and in manufacturing technologies.

We also look at how industries and manufacturing companies are working today and in the near future with an overview of technologies that impact the industrial market and manufacturing alike and have brought us what we tend to call smart industry and smart manufacturing.

Throughout the page different technological terms and evolutions are mentioned and explained. Special attention will be given to the mentioned IoT and usage of big data analytics, Industrial Internet or Industry 4.0 and the fourth industrial revolution, newer manufacturing processes such as additive manufacturing, the future of the industry and several new technologies such as Industrial IoT and what they mean. However, before doing so we start with a look at the essence of smart industry and smart manufacturing.

Smart manufacturing is the practice of “leveraging technology and data in a continuous loop to connect product development, design, manufacturing, supply chain, and post-sale activity to increase revenue and improve manufacturing outcomes (Prashant Kelker, ISG)

The difference and similarities between smart industry and smart manufacturing

When people speak about smart industry and smart manufacturing they often mean the exact same thing. And when they speak about smart manufacturing they often mean the smart factory.

However, that is not correct. So, before explaining what smart industry, Industry 4.0, smart manufacturing and so forth are and which industries we look at here, a quick note on the differences.

The difference between industry and manufacturing

As we’ll see manufacturing is the making of goods which are to be sold. Industry has a broader meaning and includes the production of goods, the related ecosystems and related services within both an economy and a specific sector.

By way of an example: the automotive industry includes car manufacturers but the car manufacturing industry does not equal the automotive industry. The same goes for most of the other industries we tackle here and mainly concern primary and secondary industries (with the latter being manufacturing) whereby our focus is manufacturing, mining, logistics and the supply chain, power industries such as oil and gas, the construction industry and so on.

In other words: typically industries that are traditionally (although this is one of many changes and there are several overlaps) somewhat less in direct touch with an individual in his/her capacity as a consumer, citizen, patient etc. This means that we don’t look at the financial services industry, the retail industry nor the healthcare industry to name a few, even if the challenges they face and transformations they go through and the technologies they use overlap as well. We do look at what is known as ‘heavy industry’ and at manufacturing. More about the definition of manufacturing and smart manufacturing below.

Smart industry and smart manufacturing

So, although terms such as sector, industry and manufacturing are used interchangeably there is a difference.

That’s why we speak about the fourth industrial revolution and not the fourth manufacturing revolution. It’s also why we speak about the smart factory, smart supply chains, smart logistics, smart this and smart that. And, finally, it’s why on top of terms such as Industry 4.0 there is also Logistics 4.0, Energy 4.0, Services 4.0 and more.

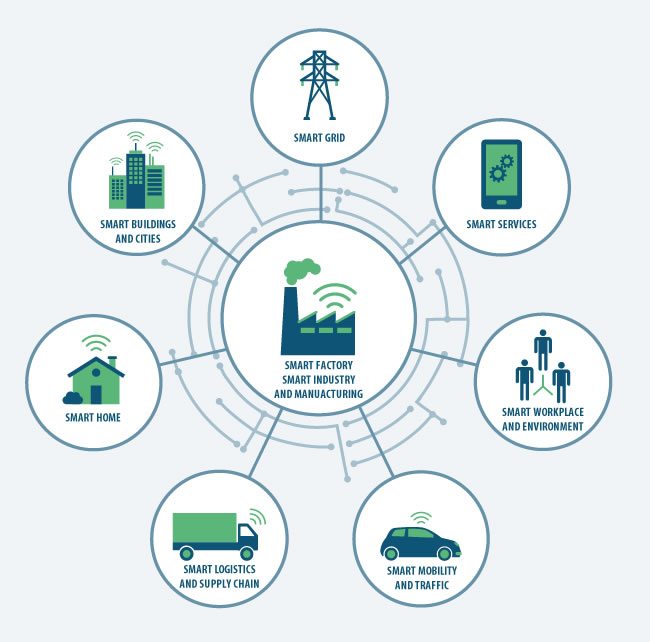

The 4.0 obviously is related with the fourth industrial revolution and the various technological enablers of that revolution. But what about all the smart (or intelligent): from the mentioned smart industry, smart manufacturing and smart factory to the smart grid, smart buildings, smart services, smart workplace, smart mobility, smart cities, smart supply chain and all those other ‘smart’ things such as the smart home and smart office?

Terms such as intelligent and smart in the scope of industry go back a long time in several sectors. They were already used in the ‘third industrial revolution’. An example: intelligent building systems.

Originally they mainly revolved around connectivity and the ability to acquire and exchange data for improved efficiency on levels such as automation, analysis, maintenance and the various stakeholders such as factory workers, partners and of course business owners.

Nowadays, on top of that the term ‘smart’ is virtually automatically associated with IoT (which in our industrial markets and smart factories becomes Industrial IoT), advanced analytics, artificial intelligence and machine learning, big data and all the technologies of the so-called third platform, as well as all the technologies which are typical for the fourth industrial revolution as they are explained in our Industry 4.0 guide.

It mainly revolves around the additional sources of data we have in this connected data age and how you turn data into action and value, with a crucial role for cyber-physical systems and IoT. However, the human dimension cannot be overlooked: nothing is smart if it doesn’t serve a purpose and most of all many human purposes. While terms such as smart factory and smart manufacturing are globally used, smart industry is more used in specific countries and essentially is a synonym of Industry 4.0, which in turn is also known as Industrial Internet or Industrial Internet of Things.

IoT in manufacturingThe image below shows some typical aspects of the Industry 4.0 technology stack but there are far more than cybersecurity, the IoT, big data, cloud computing, autonomous robots, augmented reality, additive manufacturing and so on. We mentioned artificial intelligence and machine learning, there is also virtual reality, although overlapping with simulation there are digital twins, next to autonomous robots there are also collaborative robots, on top of cloud computing, edge computing becomes ever more important and so on.

Furthermore, also existing technologies which have been used in manufacturing and in industrial markets (such as SCADA systems, PLCs, manufacturing execution systems and so forth) are changing.

More about these and other industrial transformation technologies below.

Manufacturing technology evolutions in convergenceWhat is smart manufacturing? A manufacturing definition and overview

In the strict sense manufacturing is the fabrication of goods to be sold and bought, leveraging manufacturing equipment and tools, human labor and a mix of manufacturing processes.

In other words: it can be applied to the activity and craft of making goods by individuals or small teams of people as well. Although this form of artisanship still exists, today, as we are entering the fourth industrial revolution, manufacturing mainly means industrial production and industrial manufacturing happens in automated ways with a lot of technologies leveraged at scale and within a connected supply and value chain.

Smart manufacturing and mass customization

One of the many consequences of an increasing leverage of ‘smart’ technologies in ‘smart factories’ and ‘smart supply chains’ for demanding customers in the industrial production ecosystem is that, on top of mass production as it exist since previous industrial revolutions, manufacturing has entered and continues to enter an era of mass customization.

Both the digital transformation of manufacturing (or industrial transformation of Industry 4.0 methods, processes and technologies) and the increasing possibilities of mass customization, flexible manufacturing, just-in-time-manufacturing, lean manufacturing and ever more automation disrupt industrial production as we know it with its many intermediaries.

These intermediaries in the end-to-end chain from raw materials to finished goods include other manufacturers, wholesalers/distributors, retailers and end customers. Today, several manufacturers are able to sell customized goods directly to consumers. This of course depends on the type of manufacturing and type of goods. Typical examples include sports equipment. It is just one of many ways in which Industry 4.0 offers value for smart manufacturing and smart industry.

Industry 4.0 valueSmart manufacturing and supply chain

The ecosystem of manufacturers consists of suppliers, logistical partners, the before mentioned customers and partners and other manufacturers.

In more complex forms of manufacturing often one manufacturing company has several others nearby who produced goods that are needed for the finished good in the more complex manufacturing company. Typical examples include car manufacturers who rely on others for several parts of the car, ranging from car seats to more technical components.

The most advanced and digitally mature manufacturers are developing new business models and revenue sources based upon data and services, transforming the very face of manufacturing business as all companies become digital companies. They become truly part of on averall smart supply chain and go beyond automation and optimization goals.

Smart manufacturing priorities and challenges

In an article on a 2022 manufacturing survey on ‘smart manufacturing,’ we quote Prashant Kelker of ISG (that conducted the study), saying that “Connected products and services that continuously adjust to customer usage will deliver significant growth dividends. Integrating that knowledge into engineering design is critical, and smart manufacturing is the means to that end.”

Kelker described smart manufacturing as the practice of “leveraging technology and data in a continuous loop to connect product development, design, manufacturing, supply chain, and post-sale activity to increase revenue and improve manufacturing outcomes.”

All in all, smart manufacturing as a concept still is relatively new for most organizations. For example, the study indicates that 73 percent of respondents have less than two years of ongoing smart manufacturing experience. In comparison, 70 percent say they are making slow to minimal progress on their smart manufacturing roadmap.

However, smart manufacturing ranks high on the enterprise agenda, and 69 percent of respondents say their organization has a dedicated structure to operate and coordinate smart manufacturing initiatives.

For 2022, the top smart manufacturing priorities are:

- Direct cost savings (64 percent of respondents)

- Indirect cost savings (57 percent)

- Improvements in customer experience (39 percent)

Growth objectives rank lower on the list of enterprise priorities. Among them:

- Reduced time to market (34 percent)

- Increased revenue (29 percent)

The top challenges for smart manufacturing initiatives, according to the study are:

- Organizational resistance to change (57 percent)

- Integrating IT with operational technology (34 percent)

- Technical debt and legacy equipment (30 percent)

73 percent of manufacturing organizations have less than two years of ongoing smart manufacturing experience. In comparison, 70 percent say they are making slow to minimal progress on their smart manufacturing roadmap.

Discrete manufacturing versus process manufacturing

Typically, a distinction is made between process manufacturing and discrete manufacturing.

Although these are the two most often mentioned ‘forms’ of manufacturing others exist: repetitive manufacturing, flow manufacturing etc. Moreover, in process manufacturing two distinct types traditionally were defined. However, in the scope of this overview we look at the main two as they are known (and studied) today: discrete manufacturing and process manufacturing.

Differences between discrete manufacturing and process manufacturing

In discrete manufacturing we produce several distinct finished goods which can be easily identified and are composed of different parts, whereby in theory the good/product can be reduced back to its various parts, for instance when it is broken and needs to be recycled.

Examples range from consumer goods such as sports equipment and consumer electronics to cars, planes and so forth. Discrete manufacturing often occurs in make-to-stock or make-to-order processes and instead of working with large batches as in process manufacturing we work with separate lots of assembled goods.

In process manufacturing we make products that go through some form of processing of various materials that have been used (typically chemical conversion) whereby the finished product is not differentiated and normally cannot be brought back to the various components and materials that were used because of the impact of the processing or refining.

Examples range from consumer goods such as soft drinks, paints and medication to refined oil, textiles and cosmetics. In most cases process manufacturing is batch production and formula based or recipe based as is the case in chemical conversion, refinement or blending and treating several ingredients whereby the original ingredients can’t be recovered in their original state.

The differences between both mainly matter from the differences in challenges and priorities and the various types of manufacturing have mainly been looked at from an Enterprise Resource Planning (ERP), manufacturing process and manufacturing business process perspective.

However, de factor there is a lot of overlap in the usage of modern technologies, albeit with different purposes. The differences are also high within both discrete and process manufacturing as such but particularly in process manufacturing we encounter so many industries with such different priorities, ways of working and products that it’s not really honest to speak about evolutions in “THE process industry”.

In other words: one has to dive deeper into specific manufacturing environments, yet at the same time not forget the many overlapping evolutions across manufacturing overall.

Industry 4.0 evolutions until 2022Manufacturing business transformation and digital transformation

The manufacturing industry is going through tremendous changes on several fronts and, like any other industry, is going through digital transformation.

It is doing so in times when manufacturing as a whole is posting record growth in many countries. At the same time the industry is disrupted and not just on the technology front. Also the increasing competition between regions and countries who want to lead in the Industry 4.0 evolutions, as well as, local differences and ambitions in a geo-political context of increased ant-globalization is a fact. Still, the industry is as disrupted as any other.

You can read more about these challenges in the article below on the digital transformation of manufacturing.

Digital transformation in manufacturingAdditional resources on smart industry and smart manufacturing

Do stay tuned for more information on the evolutions and key technologies in industrial transformation. On top of the previously mentioned articles, here are a few of our additional articles and some external resources on both topics.

More about smart manufacturing

Below are some of our own contributions in the scope of smart manufacturing and the smart factory.

- The smart factory as scaling deployments is the next imperative

- How Manufacturing Execution Systems (MESs) are evolving in the age of smart manufacturing

- How automation and smart manufacturing technologies drive the MES market

- The evolutions of HMI/SCADA software as human machine interfaces change

- Smart factories and the shift from ERP to smart/intelligent ERP

- The SCADA systems market and how it is changing with smart manufacturing

- An overview of one of the cornerstones in smart manufacturing: cloud computing

- The usage of robots and cobots in logistics and smart warehouse management

- Predictive maintenance and asset management

Since this is a selection please use the search engine if you are looking for in-depth articles on topics such as new manufacturing processes, the usage of the Industrial IoT and myriad technologies, from transducers and the first layers of the IoT stack to manufacturing plant security and HMI.

More about smart industry

Here is a list with a selection of more articles we wrote in the context of smart industry. As this is a selection we invite you to use the search engine for topics such as smart industry and industrial transformation plans and projects across the globe. Do remember that smart industry is really the same as Industry 4.0 and Industrial Internet (and for some the Industrial Internet of Things), which is more used in specific countries.

- Digital transformation and smart industry in transportation and logistics

- Digital transformation and the smart utilities industry

- The technological drivers of smart connected logistics

- Augmented and virtual reality trends in Industry 4.0

- Industry 4.0 and industrial data analytics

- The importance of energy efficiency in Industry 4.0

- A secure data exchange reference model for Industrial IoT

- An overview of the Made Smarter Review industrial transformation strategy

- Critical power buildings and power management in the connected age

- Industrial Protocols to connect IoT with industry at the edge

- Digital transformation in oil and gas

- The rise of the collaborative robot

- Facility management, smart buildings and smart data

Top illustration: Shutterstock – Copyright: elenabsl – Adapted smart factory image and Industry 4.0 image: Shutterstock – Copyright: elenabsl – All other images are the property of their respective mentioned owners.